Blog

Tube Laser Cutting

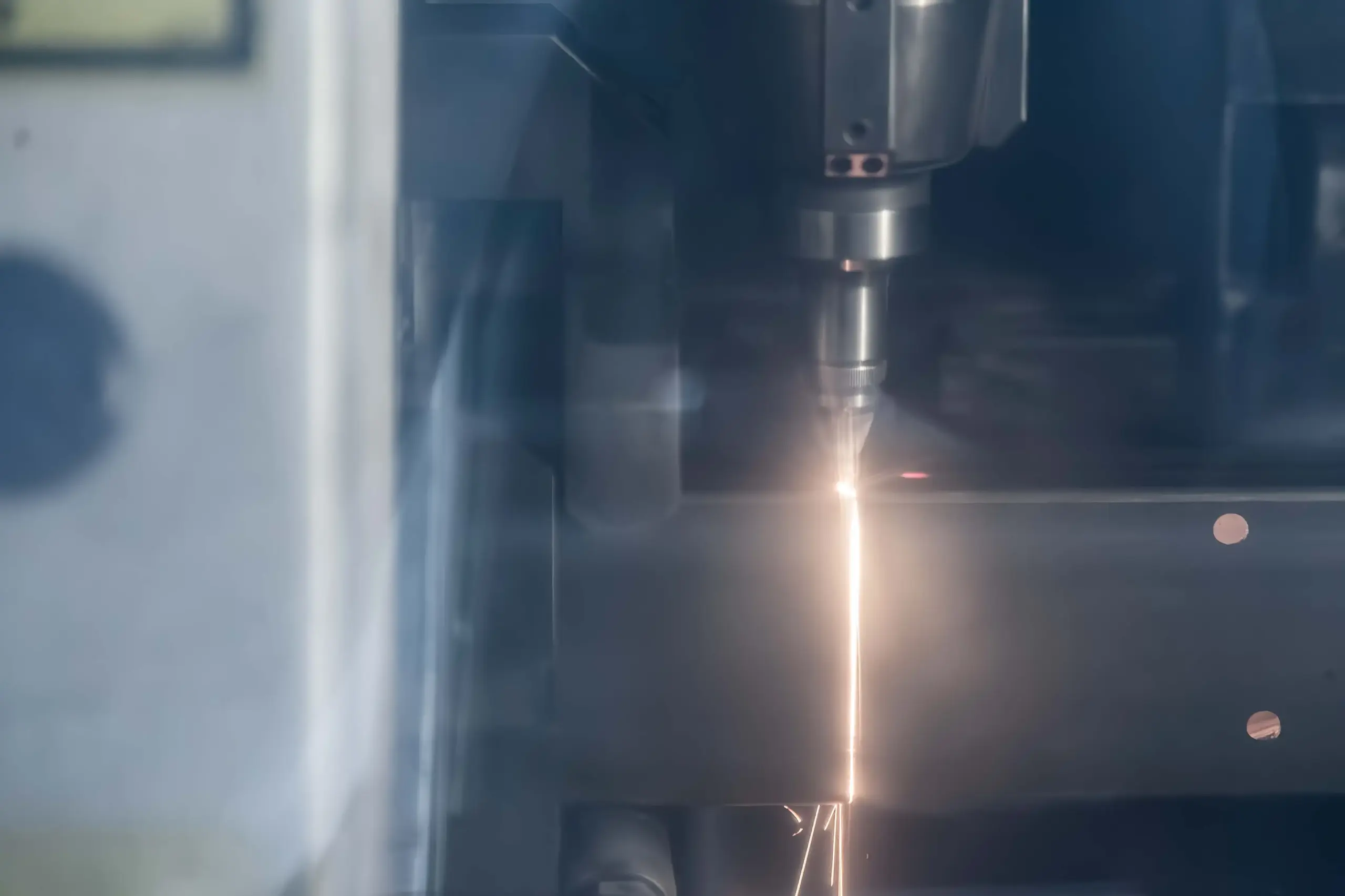

How Metal Tubes are Precisely Cut & Processed by Laser

LMV BLOG – Lauingen September 4, 2025

Modern manufacturing demands the highest precision, efficiency, and flexibility – and this is precisely where tube laser cutting comes into play. This technology allows metal tubes to be cut, drilled, and given complex geometries in a single operation. For companies in mechanical engineering, the furniture industry, or architecture, this method is a true productivity booster.

1. Key Facts at a Glance

- Materials: Steel and stainless steel up to 8 mm wall thickness (aluminum also possible in some cases)

- Diameter: up to 152 mm (circumscribing circle)

- Length: up to 4,500 mm finished parts

- Precision: precise cuts, holes, and geometries thanks to modern laser technology

- Advantages: Time savings, material efficiency, complex processing possible

- Applications: Mechanical engineering, plant engineering, furniture construction, vehicle manufacturing, architecture

2. How Does Tube Laser Cutting Work?

Tube laser cutting employs a high-power laser that processes metal tubes with the utmost precision. Thanks to CNC control, precise cuts, holes, and contours can be created that would be difficult to achieve with traditional methods such as sawing or milling.

The processing is carried out in a single operation – this saves time, reduces material waste, and ensures consistently high quality. The benefits are particularly evident in series production.

3. Technical Details at a Glance

- Laser Types: Modern fiber lasers that enable the highest precision even with complex contours

- Tolerances: Cuts with accuracies in the tenth-millimeter range

- Materials: Steel and stainless steel up to 8 mm; for aluminum or non-ferrous metals, depending on alloy and requirement

- Profiles: Round tubes, square tubes, rectangular tubes, and special profiles

4. Tube Laser Cutting Compared to Alternative Methods

Compared to traditional methods such as sawing, drilling, or milling, tube laser cutting offers significant advantages:

| Method | Precision | Speed | Complexity | Material Loss |

|---|---|---|---|---|

| Sawing / Milling | medium | slow | low | high |

| Drilling | spot | medium | low | medium |

| Tube Laser Cutting | very high (0.1mm) | fast (Automated) | high | very low |

5. 5 Advantages of Tube Laser Cutting

Advantage 1: Precision & Quality

Precise cuts and holes even for complex shapes.

Advantage 2: Process Optimization

Fast throughput and minimal setup times.

Advantage 3: Cost Efficiency

Less material waste and reduced production costs.

Advantage 4: Flexibility

Processing of round, square, and rectangular tubes.

Advantage 5: Customized Solutions

Customized production for various industries.

Request a non-binding consultation.

6. Typical Industries and Applications

- Mechanical and Plant Engineering: Precise frame constructions and connecting elements

- Furniture Construction: Filigree tube structures for table and chair frames

- Vehicle Manufacturing: Exhaust systems, brackets, and structural components

- Architecture: Design-oriented tube solutions with visible cut edges

- Industrial Plants: Pipelines, supports, and structural components

7. Workflow: From CAD Model to Finished Component

Step 1 – Data Transfer: Customers provide CAD files or technical drawings.

Step 2 – Programming: The data is transferred to the control software of the tube laser.

Step 3 – Processing: Cutting, drilling, and cutouts are performed automatically in a single operation.

Step 4 – Quality Control: Precise inspection of the components for dimensional accuracy.

Step 5 – Delivery: Finished parts are provided directly for further processing.

The Result: fast delivery times, less rework, and consistently high quality.

8. Practical Example: Tube Laser Cutting in Furniture Construction

A customer from the furniture industry required filigree yet stable tube structures for a new table frame design. Thanks to tube laser technology, LMV was able to not only cut the tubes to size but also integrate precise cutouts and miter cuts. The result: fast, cost-efficient production with consistent quality – and a product that is both aesthetically pleasing and meets the highest stability requirements.

9. Why Tube Laser Cutting with LMV Lauingen?

The LMV Metalltechnik GmbH in Lauingen offers state-of-the-art tube laser services that meet the highest demands. Customers benefit from:

- a first-class machine park for the most precise results

- experienced specialists with many years of expertise

- flexible adaptation to individual customer requirements

- sustainability through efficient processes and strict environmental standards

Whether in mechanical engineering, architecture, or the furniture industry – LMV delivers customized solutions that combine quality, efficiency, and environmental awareness.

10. FAQ – Frequently Asked Questions about Tube Laser Cutting

10.1 Which materials can be processed with tube lasers?

Mainly steel and stainless steel up to 8 mm wall thickness; aluminum is also possible in some cases.

10.2 Which tube sizes are possible?

Diameter up to 152 mm (circumscribing circle) and finished parts up to 4,500 mm in length.

10.3 For which industries is tube laser cutting suitable?

Mechanical engineering, vehicle manufacturing, furniture industry, plant engineering, architecture.

10.4 Is tube laser cutting also worthwhile for smaller series?

Yes, the technology is efficient for both individual pieces and large series.

10.5 How does tube laser cutting differ from 2D laser cutting?

With 2D laser, sheets are cut, whereas the tube laser is specifically designed for round and square tube profiles.

10.6 Which factors influence the costs?

Material type, wall thickness, tube diameter, geometry complexity, and quantity.

10.7 What is the delivery time at LMV?

Depending on the order volume: simple parts often on short notice, series productions by arrangement.

10.8 What advantages does LMV offer compared to other providers?

LMV combines state-of-the-art technology, experienced specialist personnel, sustainable processes, and customized solutions for various industries.